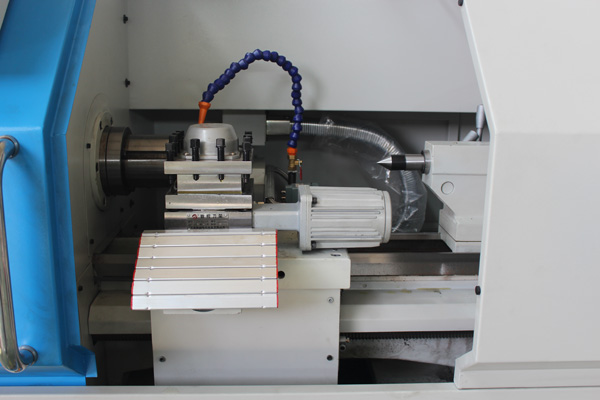

CK6132A数控车床

CK6132ACNC Lathe

标准配置:

数控系统:GSK928;

手动卡盘;

手动尾座;

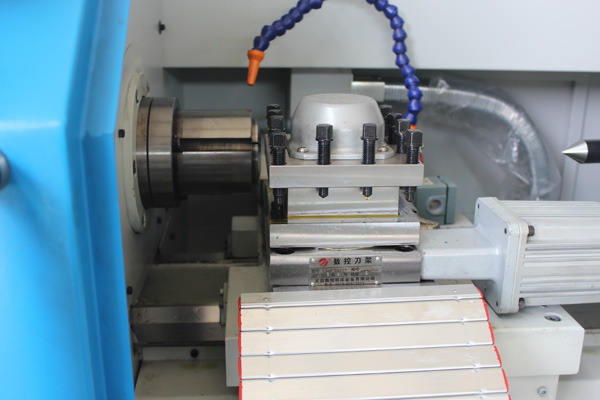

立式四工位电动刀架;

自动润滑系统;

车削冷却系统;

Standard configuration:

CNC system: GSK928,

Manual chuck ,

Manual tailstock,

Vertical four-station electric turret,

Automatic lubrication system,

Turning the cooling system.

选择配置:

数控系统:GSK980,KND,西门子,发那科等;

液压卡盘(中实、中空),气动卡盘,手动夹头,气动夹头;

液压尾座,气动尾座;

自动送料机;

卧式六工位刀架,排刀;

Select configure

CNC system: GSK980, KND, Siemens, Fanuc, etc.,

Hydraulic chuck (solid and hollow), pneumatic chuck, manual collet, pneumatic collet;

Hydraulic tailstock, pneumatic tailstock,

Automatic feeder,

Horizontal six-station turret, tool row.

机床特点:

高稳定性整体铸造床身

导轨超频淬火,硬度高耐磨

独立主轴,变频无极调速

气动卡头卡盘双向选择

|

项目Items |

单位 Unit |

技术参数Specifications |

|

CK6132A | ||

|

床身上大回转直径 Max. rotation diameter over bed |

mm |

φ320 |

|

滑板上大工件回转直径 Max.rotation diameter over pallet |

mm |

φ140 |

|

大加工长度 Max. workpiece length |

mm |

450 |

|

主传动形式 Main drive form |

独立主轴 Independent spindle | |

|

主轴调速方式 Spindle speed mode |

变频无级调速 Frequency stepless speed | |

|

主轴转速范围 Spindle speed range |

r/min |

100-2500 |

|

主轴通孔直径 Spindle bore |

mm |

φ42 |

|

主轴内孔锥度 Spindle hole bore taper |

MT5 | |

|

卡盘直径 Chuck diameter |

mm |

φ160 |

|

主电机功率 Main motor power |

kw |

4.0 |

|

刀架大行程 Turret maximum stroke |

mm |

X:260 Z:450 |

|

快速移动进给 Fast-moving feed |

mm/min |

X:6000 Z:8000 |

|

重复定位精度 repeat positioning accuracy |

mm |

X:0.01 Z:0.015 |

|

工件加工精度 Workpiece accuracy |

IT6-IT7 | |

|

工件表面粗糙度 Workpiece surface roughness |

Ra1.6 | |

|

尾座套筒直径 Tailstock quill diameter |

mm |

φ60 |

|

尾座套筒行程 Tailstock quill stroke |

mm |

100 |

|

尾座套筒锥孔锥度 Tailstock quill taper |

MT4 | |

|

重复定位精度 repeat positioning accuracy |

mm |

0.008 |

|

刀杆截面 Arbor section |

mm |

16×16 |

|

机床外形尺寸(长×宽×高) Overall dimensions(L×W×H) |

mm |

1815×1165×1750 |

|

机床净重 Net weight |

kg |

1200 |